The Davis Family Testimonial – East Coast AG

In the heart of South Mills, North Carolina, the Davis family is living out the legacy of hard work, faith, and farming. Matt and Michele Davis, along with their two children Riley and Barrett, are continuing a tradition that blends generational knowledge with fresh innovation.

Matt, an Ohio native, grew up around cattle and hay, now farms on his wife’s family farm in North Carolina. The couple traditionally focused on grain farming, raising corn, wheat, and soybeans, but in 2023, they recognized a growing need for locally-produced hay and straw.

With the influx of homesteaders near the Virginia Beach and Hampton Roads area, hay was in high demand, and local producers were few. So, they decided to carve out their own niche.

“Everyone here does grain. No one really does hay. And it all gets trucked in,” Matt explained. “So we figured, why not try to corner the market a little bit?”

Their journey into hay production quickly led them to a major challenge: labor. With rising temperatures and a shrinking labor force, Matt and Michele knew they needed a smarter solution to keep the operation moving.

Pictured L to R: Riley, Michele, Matt and Barrett Davis at their farm in North Carolina

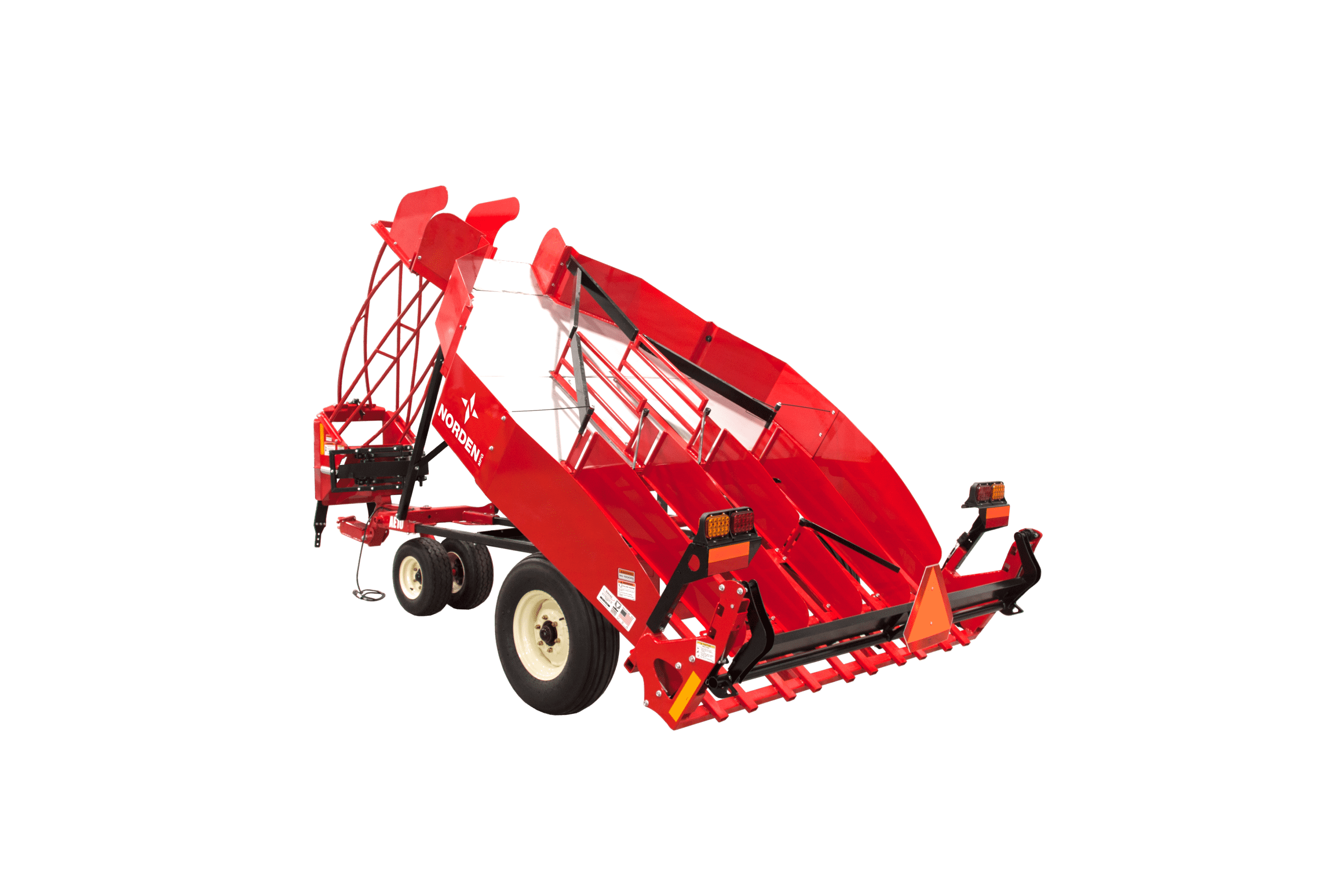

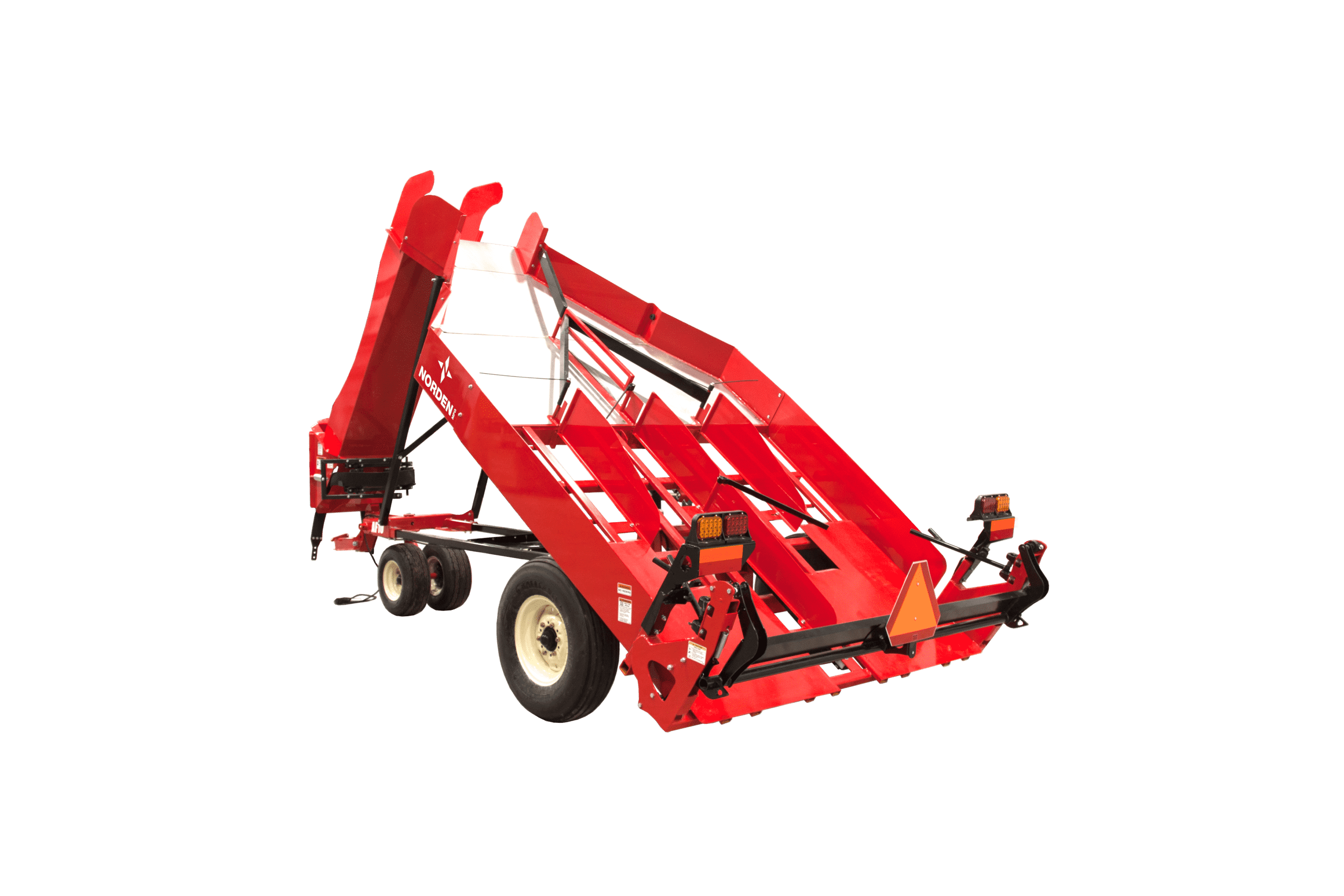

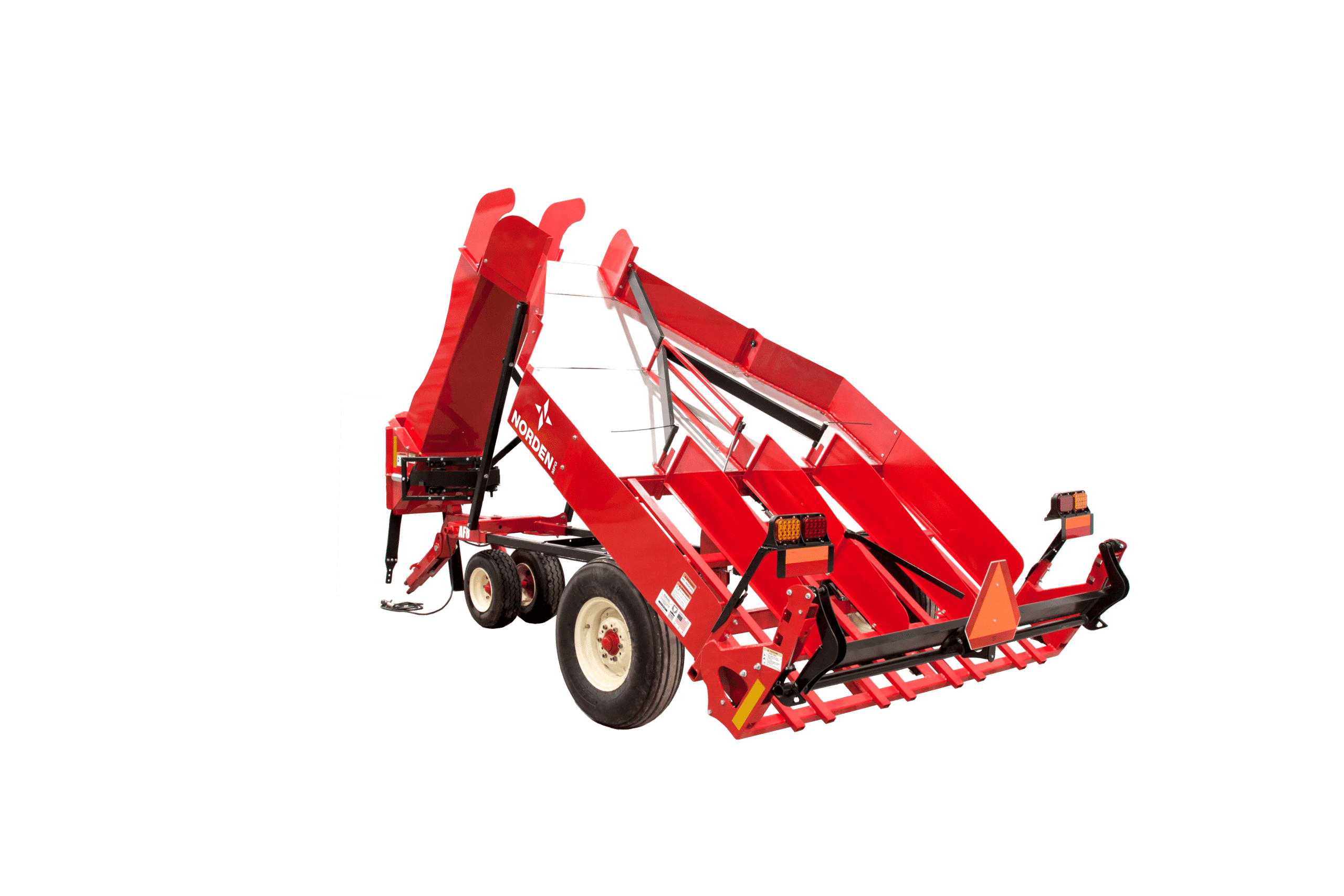

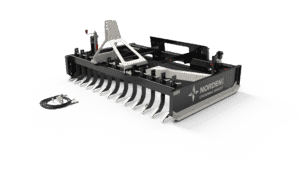

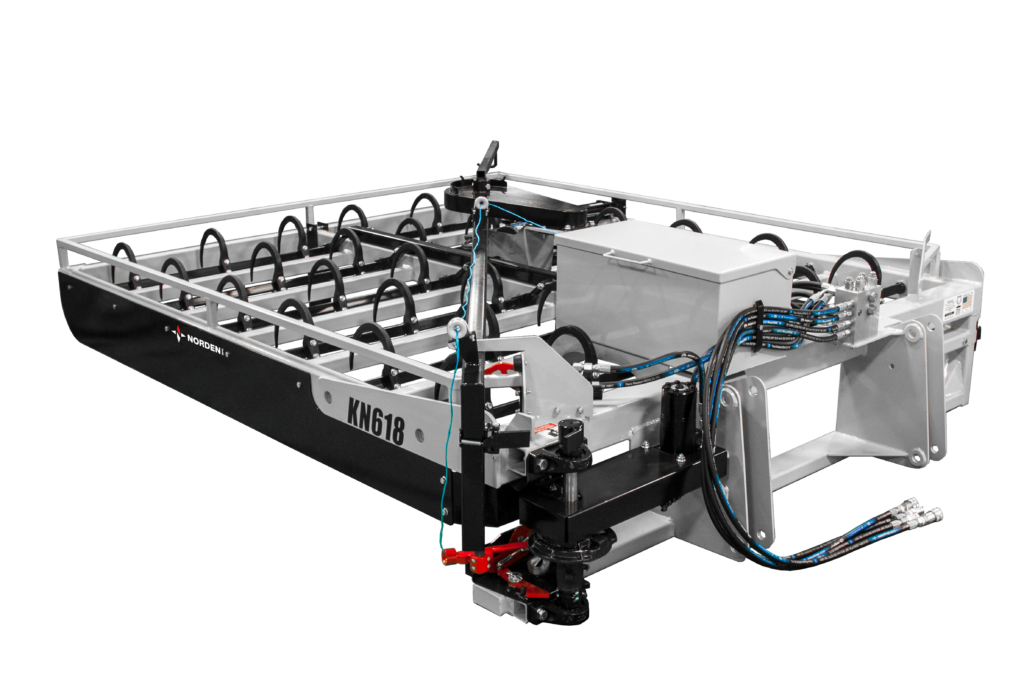

Enter the Game-Changer: The Norden Mfg Bale Accumulator

Enter Norden Mfg and their bale accumulator system.

“I spent a lot of late nights researching accumulators online,” Matt said. “I wanted something simple. Some of those systems out there cost as much as a house. But with Norden, it was mechanical, no unnecessary electronics, and the design just made sense.”

They chose the AE18 Norden Accumulator paired with a Tie-Grabber, which allows them to drop 18 bales at a time and stack them securely with a single tie. The result? Fewer trips across the field, less compaction, and no need to rely on outsourced labor.They chose the AE18 Norden Accumulator paired with a Tie-Grabber, which allows them to drop 18 bales at a time and stack them securely with a single tie. The result? Fewer trips across the field, less compaction, and no need to rely on outsourced labor.

“Honestly, I can send Michele out with the tractor and the baler, and she can run the whole thing on her own,” Matt laughed. “It’s a simple thing. It’s not like you gotta train someone for a week or anything to use.”

When asked about the top three benefits of the Norden system, Matt didn’t hesitate: increased production, fewer headaches, and efficiency.

“You don’t have to wait on a crew to show up in the summer heat. It’s just me and my wife now. That’s all we need.”

But the Davis story goes beyond equipment. It’s a testament to family, faith, and adaptability. Matt and Michelle share their knowledge freely with others, even as they protect their growing hay market. They also work closely with Matt’s brother in Ohio, who runs a similar Norden system. Together, they’ve created a supply chain of premium hay that moves from Ohio to North Carolina, giving customers more options and keeping inventory steady year-round.

Advice for the Next Generation of Farmers

Their advice to young farmers? Find a mentor, build a niche, and lean into your faith.

“If you don’t have faith, you ain’t gonna farm,” Matt said. “There’s a lot that’s out of your control. Weather, prices, mistakes… but if you stick with it, pray through it, and learn as you go, you’ll make it.”

From their roots in grain to a blossoming hay business, the Davis family is proof that with the right tools, a strong work ethic, and a whole lot of heart, there’s always room to grow.