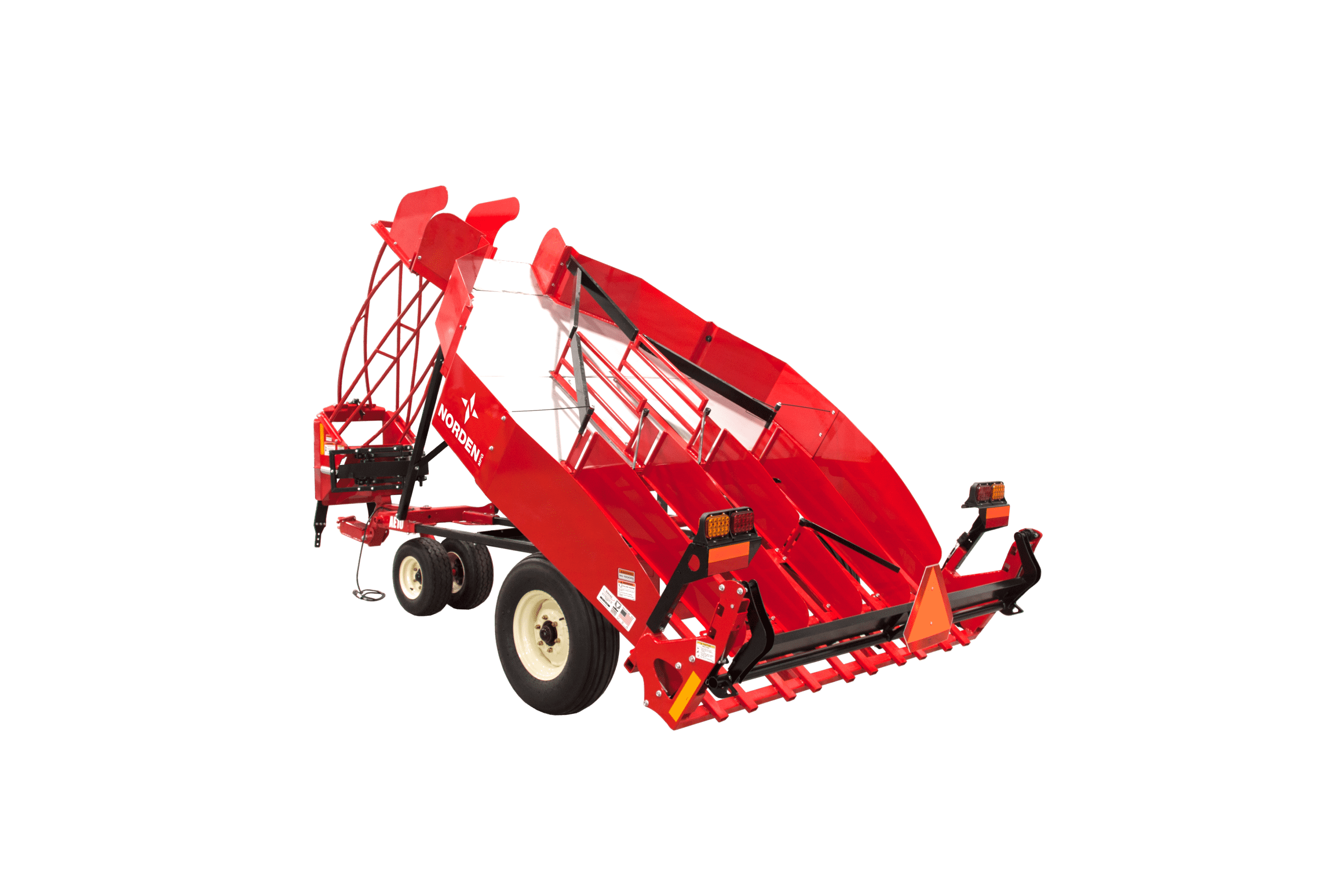

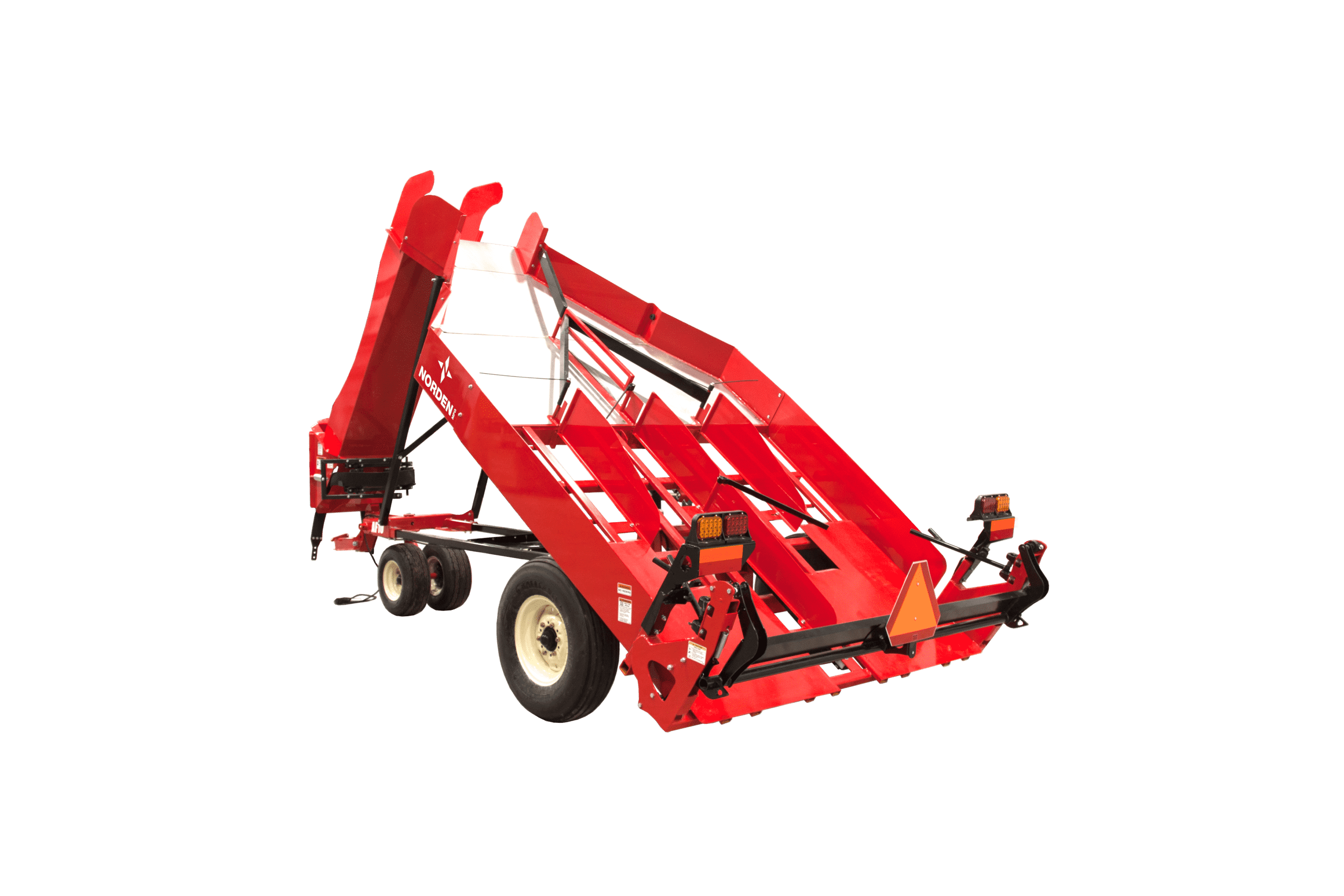

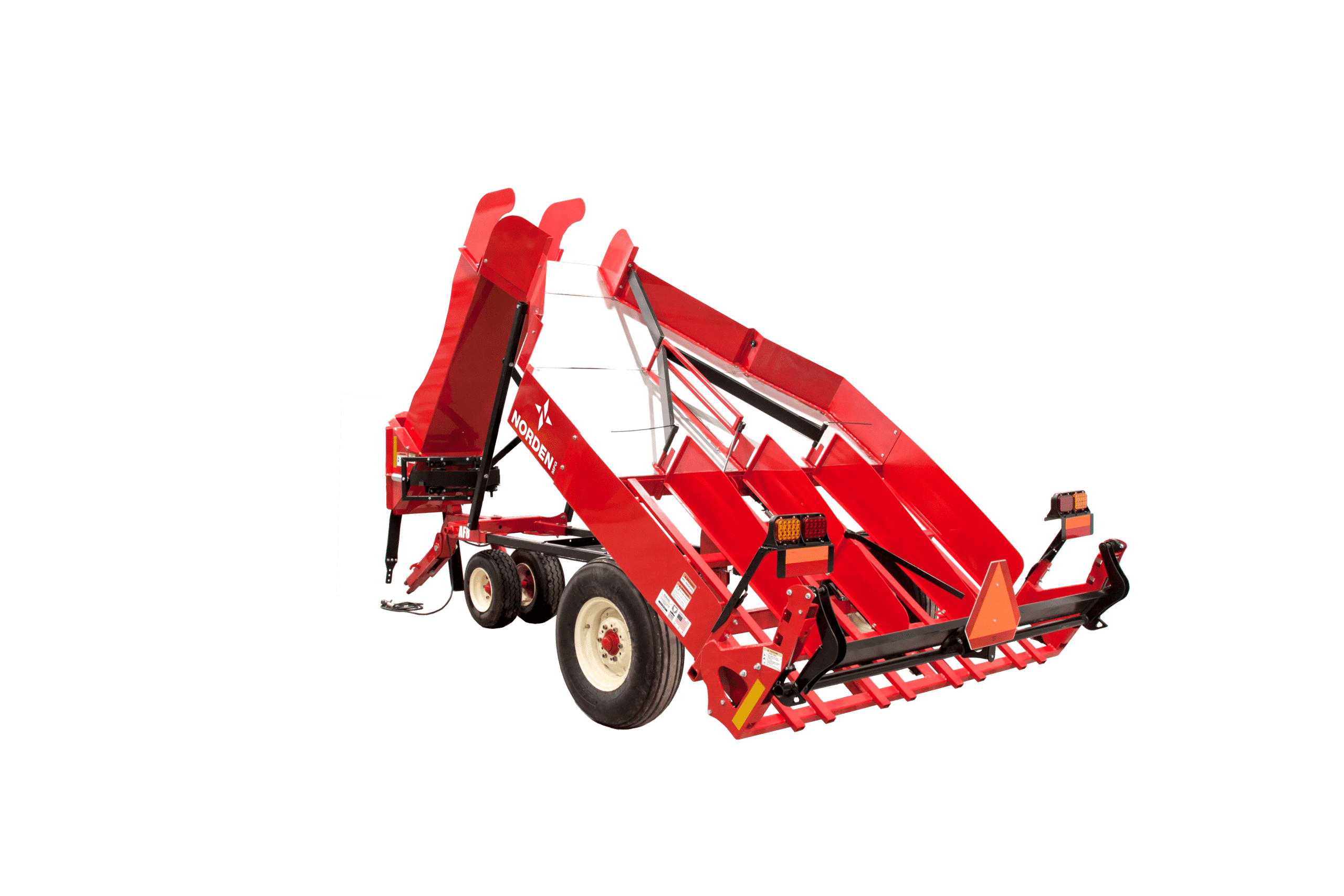

Accumulator System Overview

Looking for Kuhns MFG?

We’ve rebranded as Norden MFG! Same ownership, same great products, brand new name.

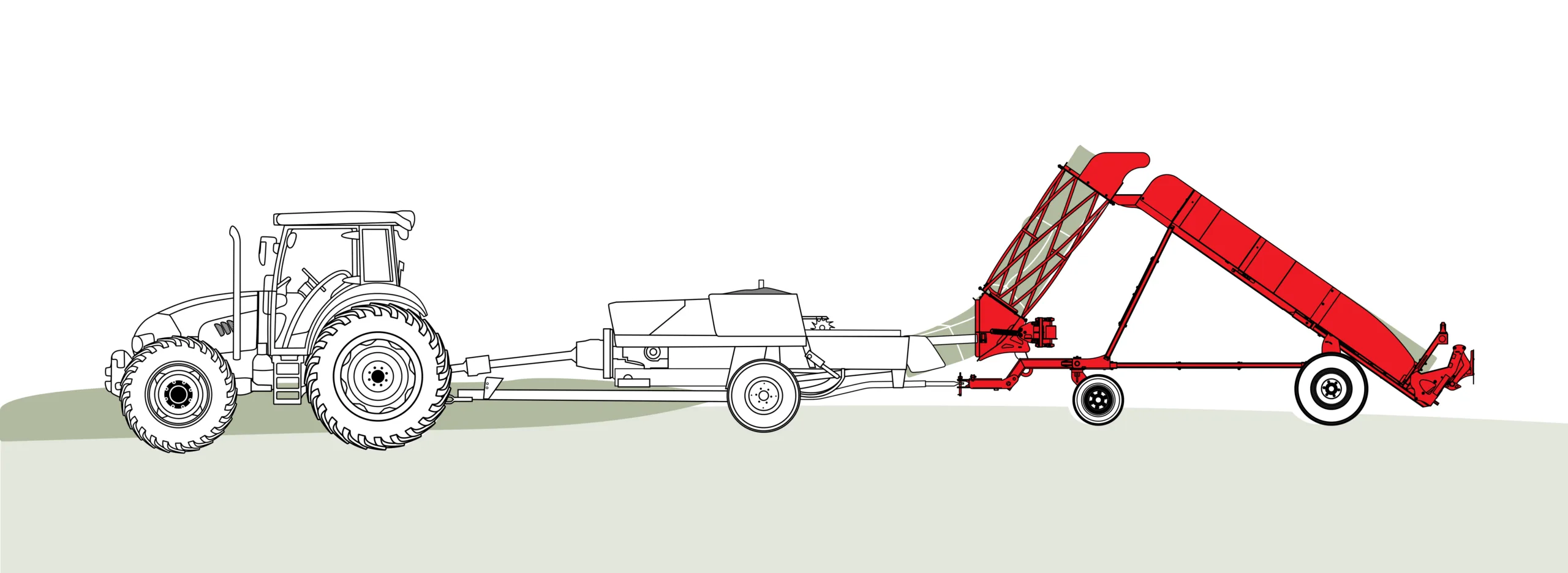

How It Works

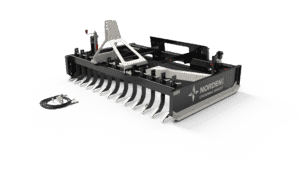

The Norden Hay Accumulator uses gravity and a simple mechanical system to efficiently arrange bales into a group that is then dropped in the field. A Norden Grabber or Tie-Grabber mounted on a front-end loader or skid steer picks up the bales to load them onto a waiting truck, trailer or wagon. The groups can then be unloaded into the barn via the grabber without an operator ever needing to touch a bale.

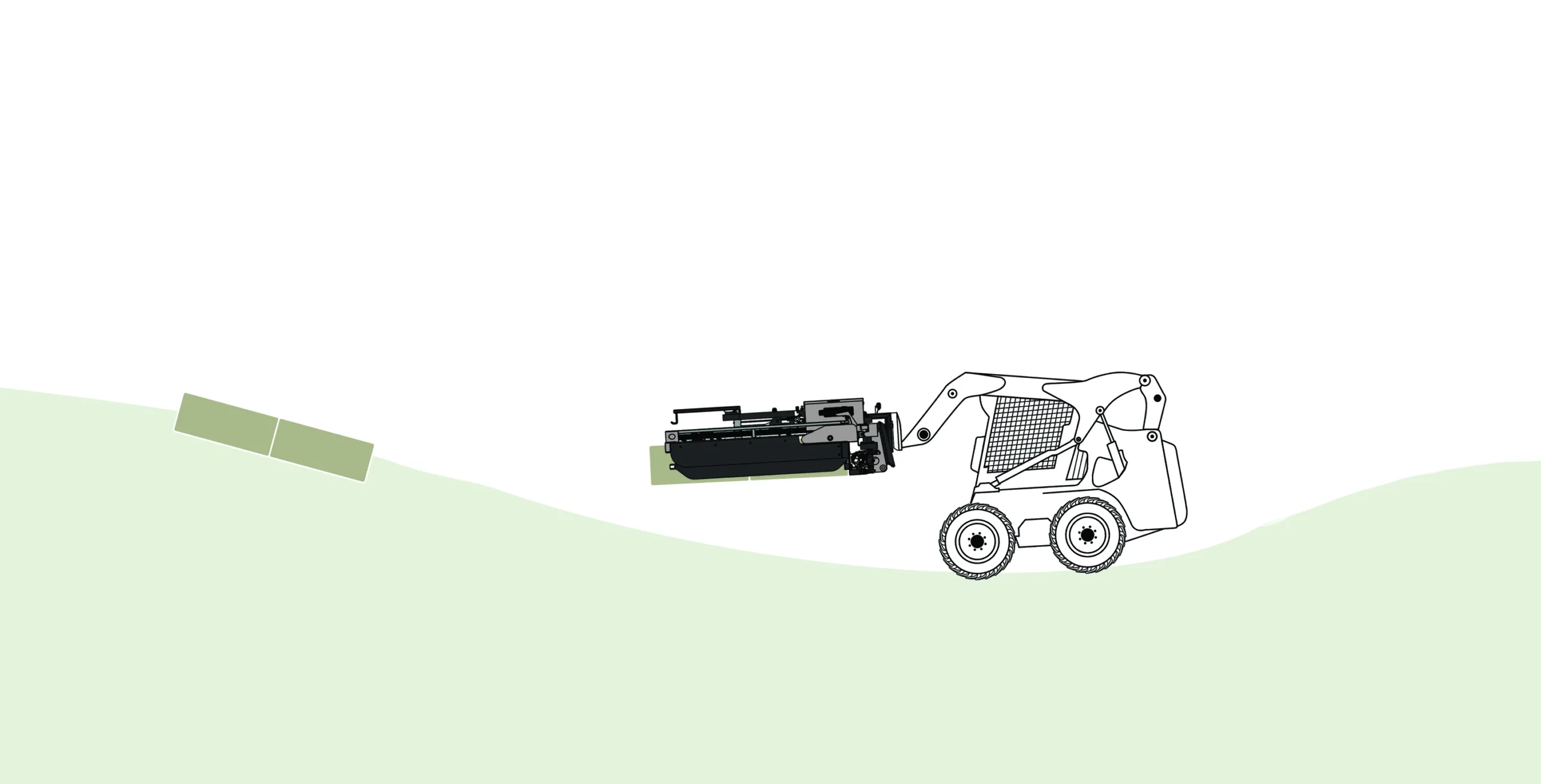

Accumulate your small square bales

The standard stainless steel gate section provides a better surface for bales to slide in higher dirt and moisture conditions.

Norden Accumulators fit all 14″ x 18″ two twine bales and our flat models can also accommodate 16″ x 18″ two twine bales.

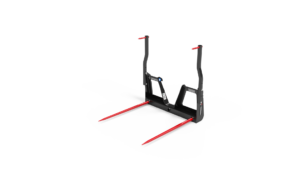

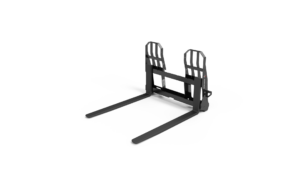

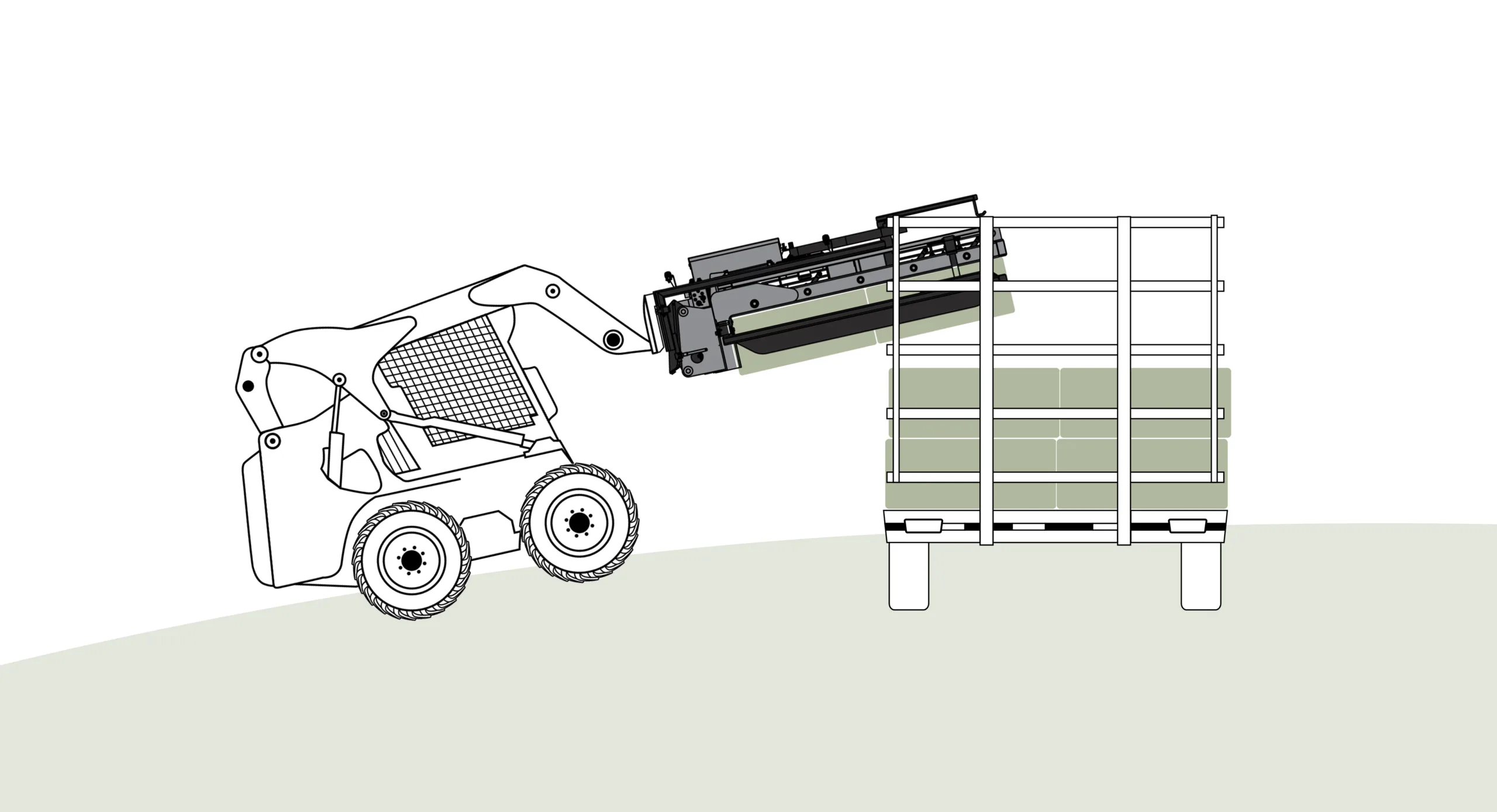

Pick up a group of bales and secure them with the Tie-Grabber.

As gravity moves the bales downward, the last bale in each row swings a gate to open the next row. The last bale triggers the back gate and the accumulator unloads its group on the ground. ready for pickup by a tie-grabber or standard grabber. The top-hinged back gate closes as soon as the last bales slide out, ready for the next grouping.

Norden Accumulators feature a naturally low center of gravity which continues to increase as more bales are added. This attribute makes our accumulators greatly effective for baling on hillsides.

The Norden Mfg patented tie-grabber wraps a string around each group of bales that it picks up.

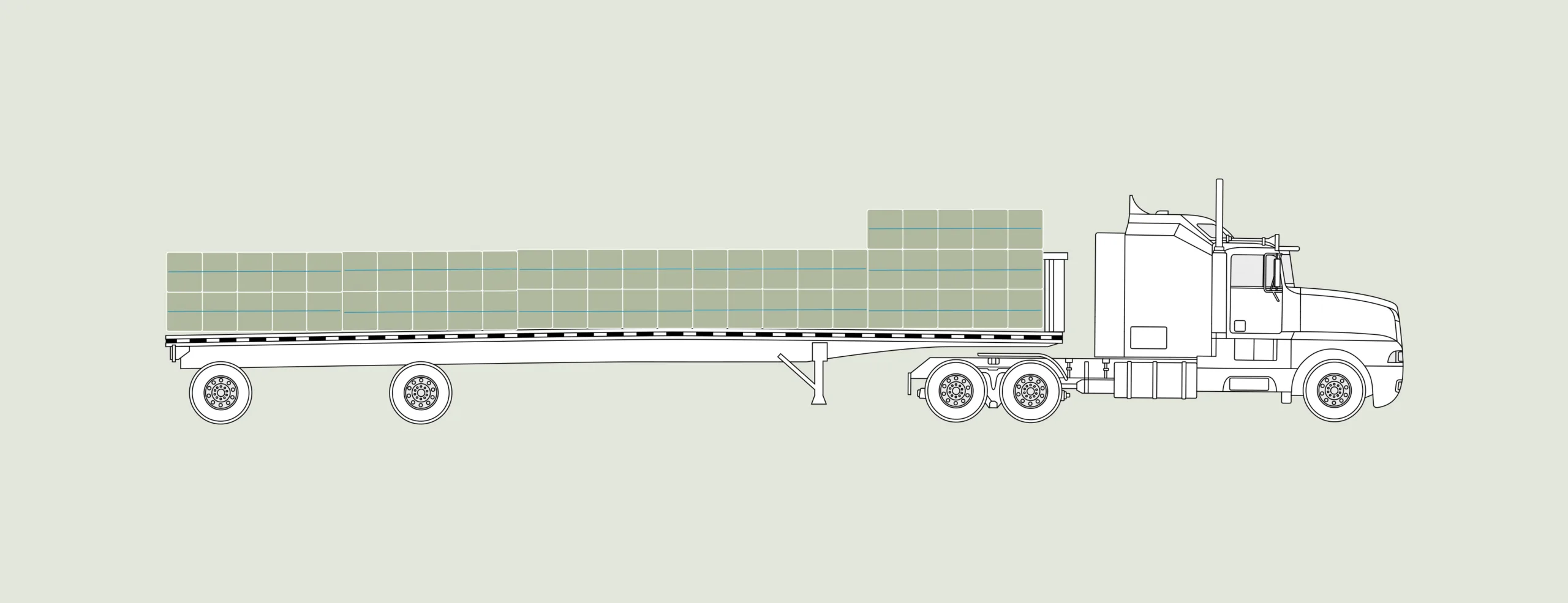

Load your wagon with confidence.

The uniform, tightly wrapped grab gives you peace of mind that your stacks are safely secured on the wagon and in the barn.

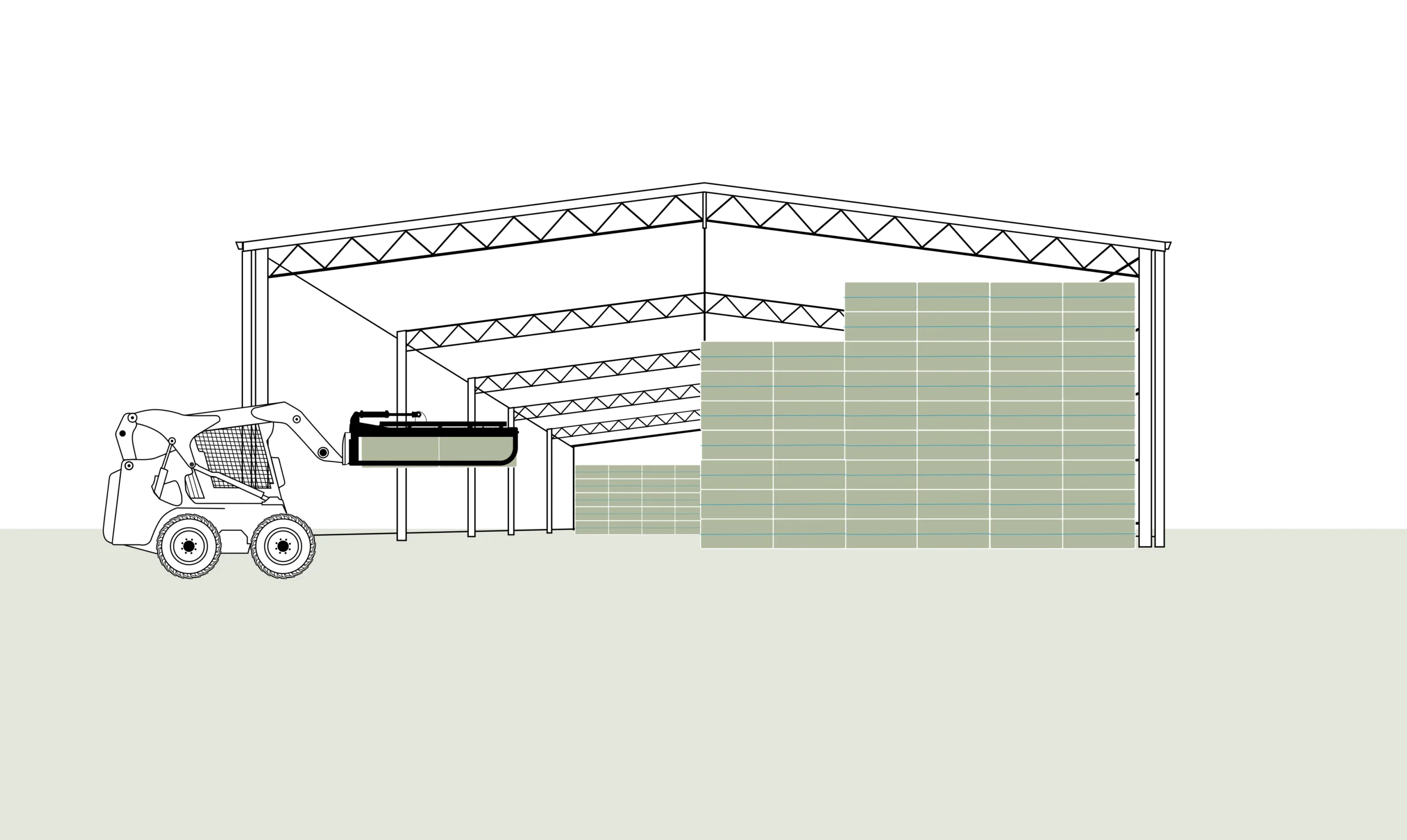

Move bales into the barn fast with a Grabber or Squeeze.

The system really pays off when you can use your loader to fill your storage. It is just as easy to retrieve the bales when you want to sell or feed them.

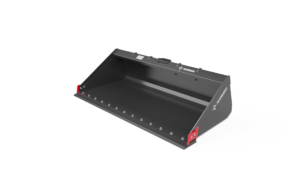

Use the grabber on either a skid steer or your front end loader on your tractor, or even a telehandler or forklift.

Move and load multiple small square bales at a time to get them to your customers quicker.

The Design

The innovative design of the hay accumulators allows it to be fully automatic without the use of hydraulics or electronics.

It works using excess energy from the baler plunger to push the small square bales to the top of the front chute. Then as gravity moves the bales downward, the last bale in each row swings a door to open the next row. The last bale in the grab opens the back gate. As the hay accumulator unloads itself, springs and counter weights return all of the gates back to their starting position, ready for another grab in good time before the next bale comes. Zero user intervention required.

All you need to do to setup the baler is ensure correct hitch-pin position (centered, 8″ behind bale chamber) and loosen the pressure in the bale chamber to compensate for the back pressure caused by pushing the bales up the chute. There is no extra pressure applied to the plunger and the twisting action of the chute does not deform the bales. You can do it all without leaving your tractor seat.

Top 5 Reasons to Buy a Hay accumulator

1.

EFFICIENCY

2.

LACK OF LABOR

3.

VOLUME

4.

SIMPLICITY

5.

DURABILITY BACKED BY SERVICE